Established in 1985 Moorland Toolmaking Company has grown to be one of the best known and longest serving plastics mouldmaking companies in the UK. Originally housed at the Moorland Business Centre in Cleckheaton, the company expanded and moved in to its current premises in Batley, close to the M62 and M1 intersection in April 1997.

Throughout the last thirty three years the company has earned a reputation for providing first class precision engineered solutions to the plastics, composites and related industries.

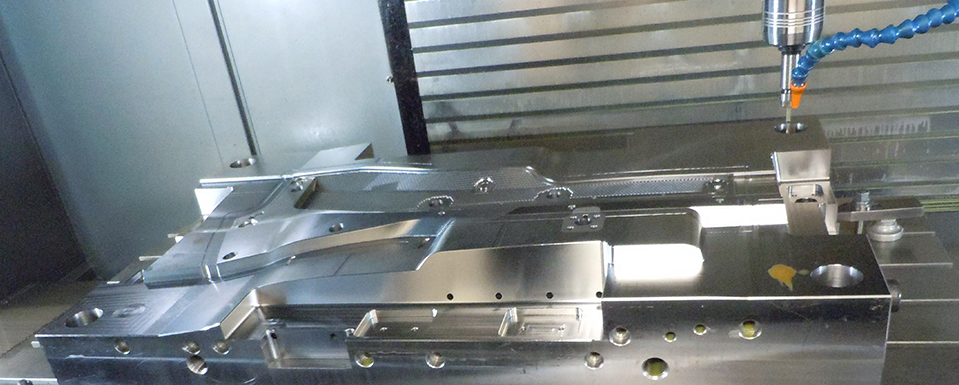

We are a business built upon traditional skills, but in adopting the latest technologies and utilisation of state of the art equipment our highly experienced team of staff enable Moorlands to compete on price and lead time in all of its markets.

We believe there are several contributors to the success and growth of our business over the years. A loyal team of highly skilled staff, a reputation for reliability of service and delivery on promised lead times, constant investment in the best equipment and design software, and the highest possible level of customer care. We believe in the importance of building client relationships borne from effective communication and trust.

Whether it be the design and manufacture of small multi cavity moulds or tooling up to a weight of 12 tonnes, modifications and repairs, precision subcontract machining, fine laser welding or mould polishing Moorlands offer the highest standard, cost effective, and speedy service.

In choosing Moorlands for your next new project you can expect advice on design for component integrity and mould tooling designed for optimisation of process and maximation of throughput. Your success and profitability is important to us !

You can be assured of the highest quality standards of design, service, and manufacture and finishing.

With every project we provide timing plans, materials conformance certification, and regular progress reports supported by photographs or video. We are happy to offer advice on choice of die material, and suitable heat treatments for your application. We only use materials, ancillaries and heat treatment services from accredited sources. All processes are subject to stringent metrology.

Project management communication is provided throughout the manufacture and validation processes.

We always aim to design and supply durable, fit for purposes products and services in order that we reach or exceed the expectations of customers.

Employing Autodesk Delcam Powershape Ultimate software our fully skilled in-house Design Engineers can help to deliver the optimum solution to suit the specification brief, budget, and expected manufacturing lead time.

Whether it be plastic injection mould tooling, thermoset compression mould tooling, thermoset compression transfer tooling, blow moulds, extruders, Rim tooling, or prototype moulds, we will design high quality tooling to meet product specification and accuracy, cycle time, and tool life expectation.

Other areas covered include product design, advice on product design relating to suitability to sustainable tooling, reverse engineering, moldflow analysis. Also advice upon steel type suitability and moulding media suitability to your application. Particular attention is always paid to mould temperature control and mould venting to maximise productivity throughput. We are proud of our reputation for the design and manufacture of high quality durable mould tooling.

We handle all commonly used drawing file formats.